Description

DPF 300 machine for PCB separation

Piergiacomi DPF 300 – Patented manual depaneling system, designed for separating small and medium series of PCBs.

DPF-300 cuts PCB isthmus with the same quality as an automatic system, at significantly lower costs. It is ideal for all those “intermediate” situations when the use of a manual tool would be too expensive in terms of labor, while the use of an automatic depanellizer would not justify amortization costs.

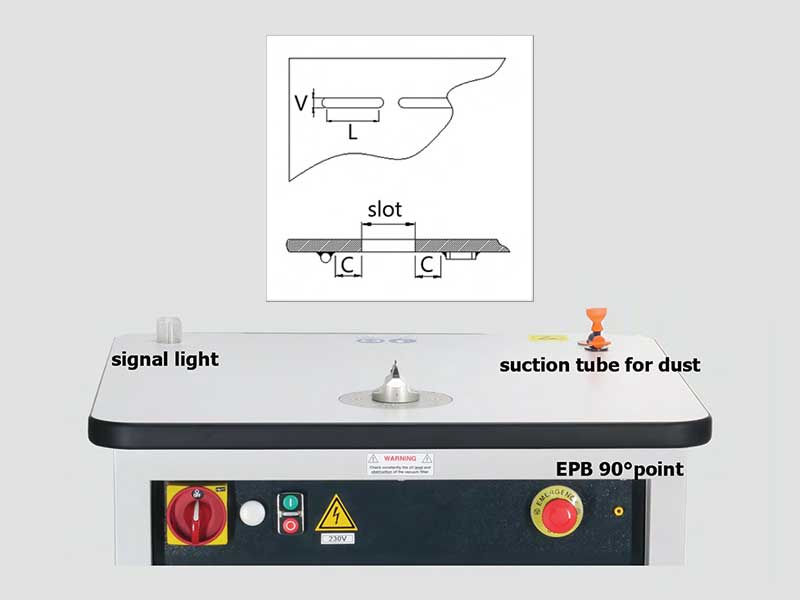

The main feature of DPF-300 is the possibility to change very fastly the milling cutter and the interchangeable guide (designed by Piergiacomi). The guide quickly assists the operator in the positioning phase and in dragging the PCB until the cut is done. Its particular shape avoids to damage the PCB in case the operator, having inserted it wrongly, doesn’t match perfectly the guide into the eyelet.

The particular design of the guide gives total protection against accidents according to safety rules.

DPF-300 has been designed to avoid problems of stress, breakage or tearing of PCBs fibers that can occur using standard blades or manual tools: situation that today, with the increasing complexity and miniaturization of processes, are not tollerated.

Thanks to the integrated extraction system positioned directly above the guide, DPF-300 can be easily placed in any working area.

Customized versions of DPF-300 are available for depanelizing circular or short boards.

The machine is completely electric and does not require the use of compressed air.

Scope of supply: DPF-300 depaneling machine equipped with extraction system and cartridge filter, 1 x Standard guide in the size required by the customer, 10 x Milling cutter of the corrisponding size for cutting FR4/CEM.

Options available (NOT included): Customized circular guide, Customized short guide (length 5 mm), Milling cutters for aluminium cutting.

Specifications

- PCB thickness: max. 4 mm

- Isthmus distance from components: min. 1 mm

- STANDARD INTERCHANGEABLE GUIDE:

– Material: Hardened and tempered steel

– Available thickness (slot width): from 0.8 to 3.175 mm (± 0/-0.02 mm)

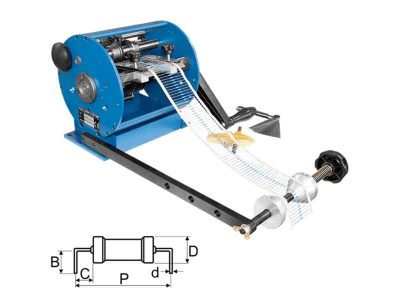

– Slot length: min. 11 mm - MILLING CUTTERS AVAILABLE (FOR STANDARD GUIDE):

– Cutters in hard metal with specific geometry for FR4 and CEM (supplied), or ALU (on request)

– Available diameters from 0.8 to 3.175 mm - Supply voltage: 230 V 2P + T Schuko

- Electric microspindle speed: max. 24000 RPM

- Vibrations: < 2.5 m/s² – Acoustic pressure level (measured at operator’s site): 80 db (A) (+/- 3 db)

- Built-in electric suction system with cartridge filter (1″-1/4)

- Depression: 28 kPa (-280 mBar)

- STRUCTURE:

– Table with laminated ESD safe worktop and EPB 90°

– ESD safe frontal feet made of zinc coated steel, ESD safe rear turning wheels with brakes Ø 80 mm

– Dimensions: 64 x 70 x 95h cm – Weight: 73 kg

– Working area required: 164 x 170 cm - ESD properties: Compliant with IEC 61340-5-1 standard.