Description

Professional equipment for the production of PTH PCBs

COMPACTA 30 Through-hole plating system is ideal for the laboratory prototyping and production of double sided PTH PCBs small series.

It can take boards up to 210 x 300 mm.

The machine has 5 treatment tanks (cleaning – pre-dip – catalyst – intensifyer – reserve tank) and 1 galvanic plating tank. Two treatment tanks are thermostatically controlled and equipped with a teflon heater.

Board movement in all tanks is performed by a DCgear motor, the speed is stepless variable.

The galvanic plating tank comes with an integrated air injection and a stepless regulated rectifier.

A Voltmeter and an Amperemeter show the current electric values.

Special attention has been dedicated to the integrated rinsing compartment, with a double pre-wash tank for cascade flushing and a spray sink, the latter activated via foot-switch and a magnetic valve.

The Bungard COMPACTA Series machines have been designed to meet the demands of professional direct metallization.

Available variations: COMPACTA 40 2 CU with 2 galvanic plating taks (max. board dimensions: 300×400 mm).

On request: based on the COMPACTA-series we can supply machines for other chemical systems.

Specifications

- Dimensions (LxWxH): 880 x 1000 x 1350 mm

- Working level: 950mm

- Heaters: 2 x 400W

- Rectifier: 1 x 6 V, 40 A

- Bath movement: DC-gear motor

- Power supply: 220 V, 50 Hz, 6.3 A

- Treatment tanks:

Dimensions (LxWxD): 400 x 100 x 300 mm

Capacity: approx. 10L - Galvanic copper tank:

Dimensions (LxWxD): 400 x 275 x 300 mm

Capacity: approx. 30L

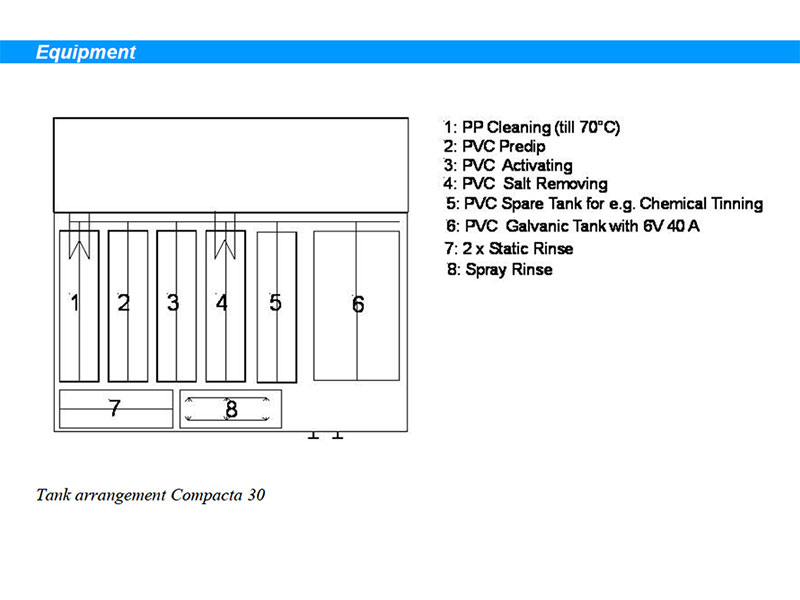

Equipment

- 5 Treatment tanks (cleaning – pre-dip – catalyst – intensifyer – reserve tank)

- 1 Galvanic plating tank

- 1 Double-cascade rinse tank

- 1 Spray rinse tank with magnetic valve, foot switch and flow control.

Accessories / Options

- Included in the supply: Digital timers for each bath

- Available on request (NOT included in delivery): Chemicals, anodes, anodes holder and board holder.